Getronics Editorial Team

In this article:

‘Digital first’ is an ethos that defines both AMRC Cymru and Getronics. When Getronics became aware of AMRC Cymru’s goals to support manufacturing in transitioning towards net zero carbon, they approached them with a proposal.

That proposal is a Proof of Concept that is now live at AMRC Cymru, showcasing how the active management of energy use in real-time is the first step to controlling and reducing towards net zero the use of greenhouse gases in a manufacturing business.

Company profile

AMRC Cymru is part of the University of Sheffield Advanced Manufacturing Research Centre (AMRC). This is a network of world-leading research and innovation centres working with manufacturing companies of any size from around the globe to develop and de-risk industry-transforming solutions.

Locations

The AMRC now employs over 500 highly qualified researchers and engineers from around the globe, on the Advanced Manufacturing Park and Sheffield Business Park in South Yorkshire, as well as in Broughton (North Wales) and Preston (Lancashire).

Capabilities

Machining, integrated manufacturing, composite manufacturing, castings, design & prototyping, structural testing, medical, additive manufacturing, microscopy, metrology and manufacturing Intelligence.

Helping manufacturers to become net zero

One of AMRC Cymru’s key objectives is to improve the sustainability of Welsh manufacturing. The drivers for change have never been more urgent:

- After decades of inaction, we are now in the midst of a climate crisis

- The Government has committed the UK to a legally-binding target of Net Zero emissions by 2050

- The public and investment community are becoming far more aware of the sustainable credentials of all businesses and are making their buying choices based on them

Climate change is a scientific fact and so businesses must respond to this imminently to reach Net Zero Manufacturing. It’s just the right thing to do!

Combining this with the AMRC’s ‘digital first’ approach has resulted in a partnership with Getronics to deliver – Active Real-Time Energy Measurement.

If you can’t measure you can’t control:

Getronics has a strong track record of delivering and managing the integration of Operational Technology (OT) and Information Technology (IT) solutions. Our Energy Management solution sits within our Sustainable Manufacturing Integrated Solutions.

Just taking the initial steps towards Proactive Energy Measurement & Management has been proven to save up to 25% in electricity and 50% in water usage.

Taking real-time feeds from all Operational Technology is the starting point for measuring your energy usage and for taking steps to Net Zero Manufacturing.

Step 1 – Set up the Monitoring Solution

Our technicians can set up the IoT sensors or use existing integration solutions, PLC, Scada, network connectivity, etc. In any sized organisation the varieties of sensors and data feeds will be numerous. We can connect almost anything to anything. The level of granularity is the key, from site to individual machine the data must be made available in real-time.

Step 2 – Creating the Dashboard

Online dashboard from which you can run ‘what if’ scenarios and identify exactly where the big users of energy are. The visibility of OT also allows the user to actively manage those devices from remote, secure environments.

Step 3 -Active Management

Establishing Pro-Active management. It has been found that by just taking these steps you can reduce the energy consumed by up to 25%.

Step 4 – Define Your Strategy

Defining your strategic targets and goals can be a much more informed process if you use real-time data from your facilities. This will be a longer-term project, looking at renewable energy sources, swapping out high energy users, etc. We can help you with this step with our strategic consulting service.

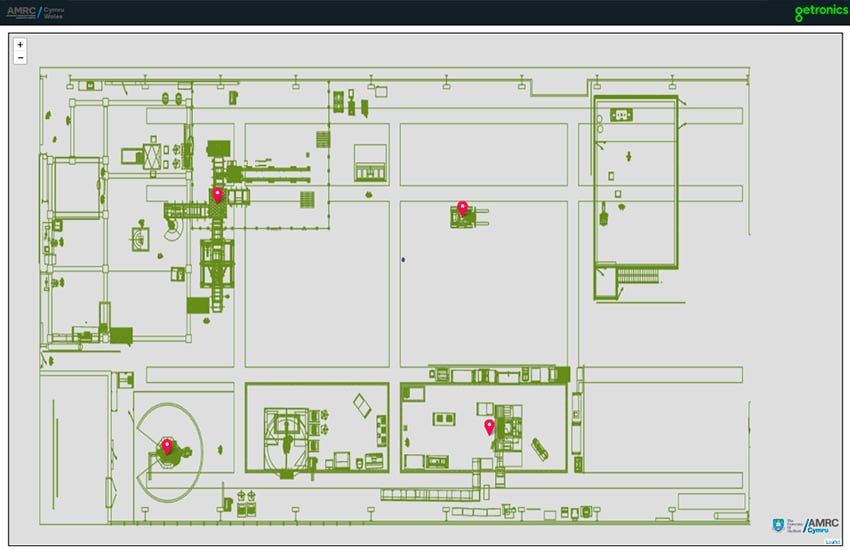

Digital Mapping of devices

Once the device has been connected, it can be mapped across your facilities:

The Future

Any element of OT can be connected to the Getronics solution. HVAC, BMS, Lighting Systems, Security, Shopfloor systems, Robots, Conveyers, Water pumps, etc. Delivering a fully connected solution not only gives the ability to manage energy and waste but it can also be upgraded to include, condition monitoring, predictive maintenance, service management, etc.

Automating the management and maintenance of the devices is the logical next step. We see the future scope of the AMRC Cymru project growing to prove the technology and demonstrate the multiple uses that real-time data can enable.

’We were very happy to support the proof of concept delivered by Getronics at AMRC Cymru. The work aligns perfectly with our goal of improving manufacturers’ productivity, performance and sustainability by incorporating innovative digital technologies.’

Andy Silcox, AMRC Cymru Research Director